Paper Mill Pulp Belt Dewatering Machine Equipment Introduction

Characteristics of Paper Pulp:

The raw fiber of pulp is fine (the length of wood pulp fiber is mostly 0.5-2mm) and soft. The belt filter press employs a “low-tension filter belt + graded gradual pressing” design. The filter belt, crafted from highly breathable, low-wear polyester or nylon, prevents fiber winding or breaking. During pressing, the system progressively increases pressure through stages: gravity pre-dewatering (draining free water), wedge-shaped low-pressure extrusion (initial shaping), and multi-roller high-pressure extrusion (deep dewatering). This approach ensures efficient dewatering while maximizing fiber length and toughness retention, supporting strong paper quality in subsequent papermaking processes.

Advantages of belt press dewatering machine:

1.Improve pulping efficiency and reduce production energy consumption

The dewatering cycle of belt press dewatering machine is short, which can greatly shorten the pretreatment time of pulp compared with traditional natural drying or centrifugal dehydrator (which is easy to cause fiber loss); And the moisture content of the dewatered pulp is stable, so that the heat energy consumption in the subsequent drying process can be reduced by 30%-40%, and the overall energy consumption cost of the paper mill can be reduced.

2.Reduce fiber loss and improve the utilization rate of raw materials

The pores of the filter belt of the equipment accurately match the particle size of pulp fibers, only allowing water to pass through, and the fiber retention rate is over 98%; At the same time, there is no violent stirring or high-speed rotation in the pressing process, which avoids fiber breakage or loss with filtrate, especially for high-value wood pulp and bamboo pulp.

3.High degree of automation, suitable for paper production line integration

The belt filter press can be directly connected with the pulping system of the paper mill, and the whole process of “automatic feeding, concentration adjustment, filter belt cleaning and mud cake conveying” can be realized through the control system, without frequent manual intervention, reducing the workload of 3-4 operators.

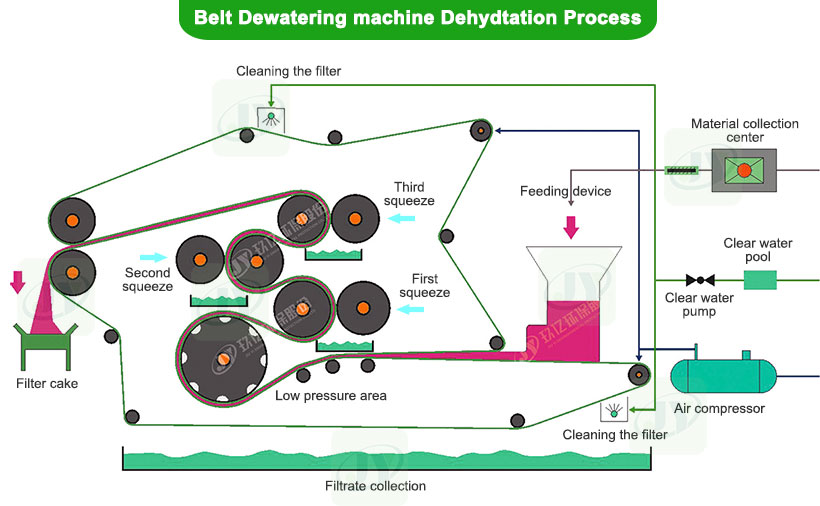

Dehydration Principle Of Paper Pulp Belt Dewatering Machine

Transport materials with a moisture content of 80% -90% to the hopper of the dewatering machine through a conveyor, and evenly spread the materials on the filter belt through a feeder. The filter belt moves with the operation of the equipment, and the limit plate scrapes the material layer flat. At the same time, control the thickness of the material to make it completely uniform and consistent.

Then, two fully tensioned circular filter belts are clamped between the material layer, driven by the driving roller. The material is continuously and repeatedly squeezed through the pre press dehydration zone, low-pressure zone, and three sets of pressure roller high-pressure zone to remove a large amount of moisture.

Adjust the extrusion pressure and feeding speed according to different material characteristics to meet customers’ requirements for material moisture.

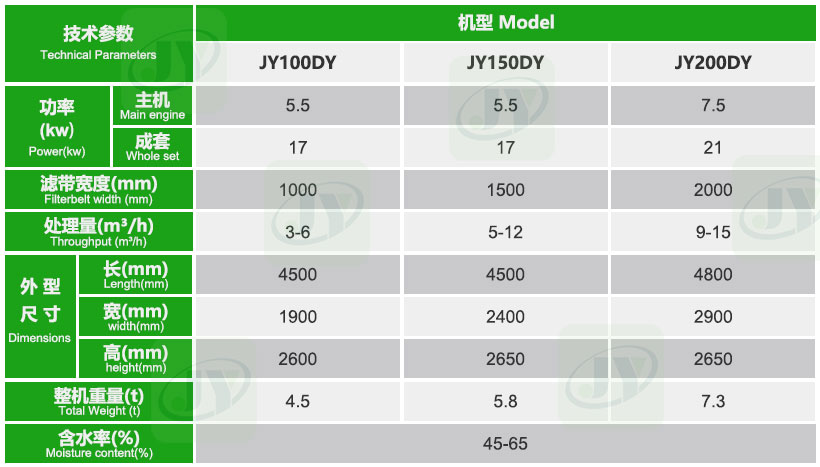

Belt Press Dehydrators Technical Parameter

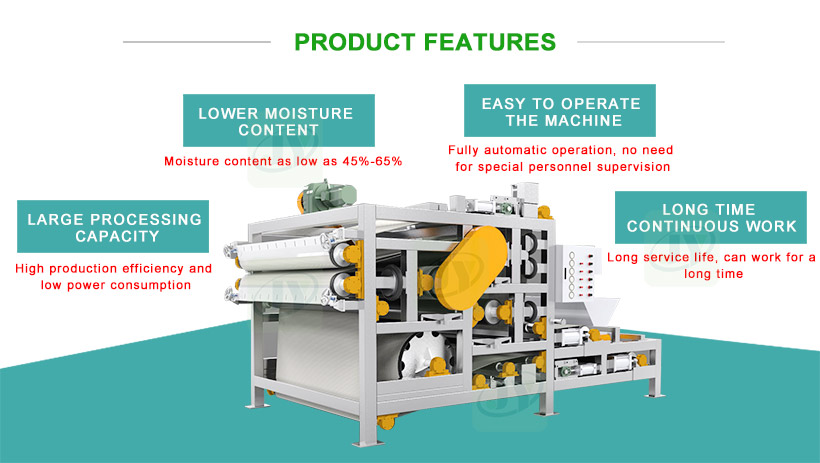

JIUYI Brand Belt Press Dewatering Machine Feature

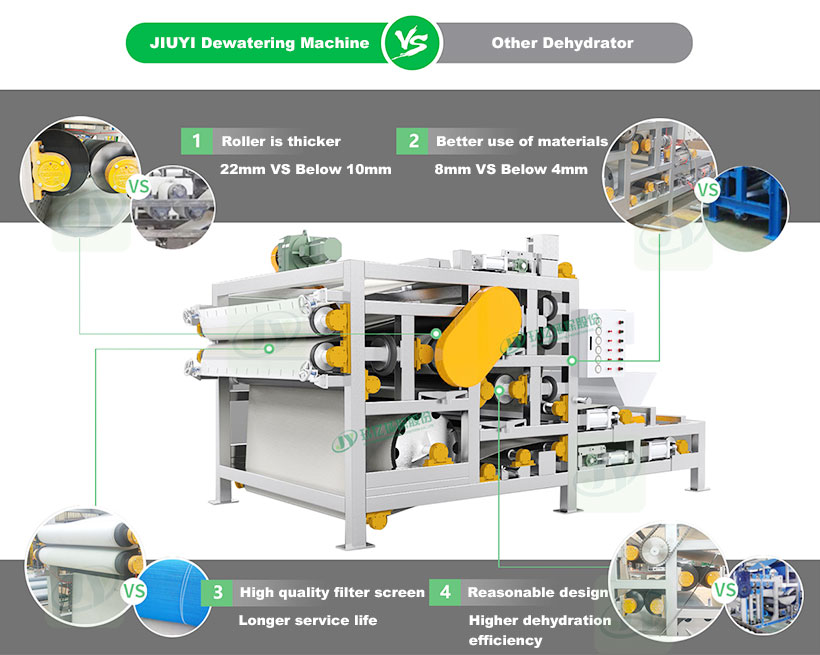

JIUYI dehydrators is a new generation of high-efficiency press dewatering equipment independently developed by us based on years of material dewatering experience and combined with similar dewatering equipment technologies at home and abroad. It has successfully solved the problem of continuous large-scale and deep dehydration of different materials.

1. Low power consumption, low noise, high production efficiency.

2. The machine adopts an ultra long filtering zone, combined with strong pressure rollers for multiple dehydrations, resulting in high dehydration efficiency and large processing capacity.

3. Automatic filter cloth cleaning system, no manual intervention required.

4. Adopting an automatic fabric device, the feeding is smooth and reliable.

4. Select high-quality anti-corrosion materials and components for processing and manufacturing.

5. Advanced and reliable filter belt correction and tensioning device can ensure long-term stable operation.

6. Variable frequency drive control, adjustable production speed.

7. It can run continuously for 24 hours, with high automation, simple operation, and easy maintenance.

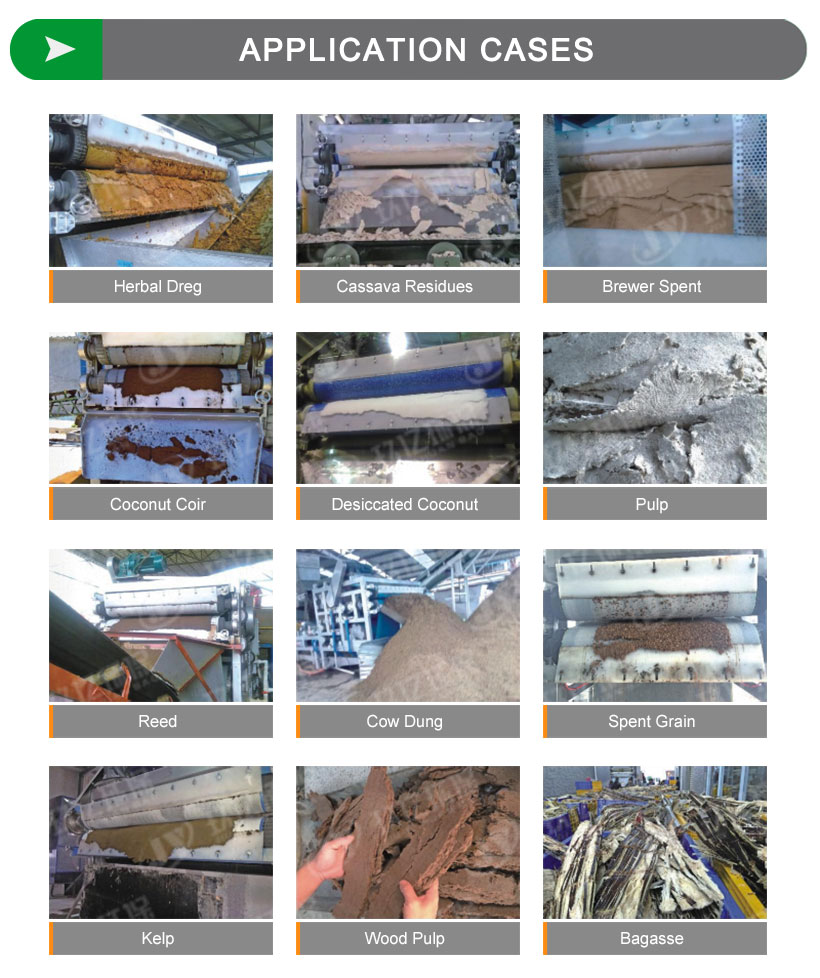

8. Advanced structural design with a wide range of applications.

9. The driving roller and squeezing roller of the dehydrator are coated with high-quality materials.

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment