Sweet Potato Residues Belt Press Dehydrators Equipment Introduction

Characteristics of Sweet Potato Residues:

As a by-product of sweet potato processing (starch, vermicelli and alcohol production), sweet potato residue has the characteristics of “double high”: first, the starch residue rate is high, usually containing 15%-20% of incompletely extracted starch, which makes it have high energy value and lays a foundation for subsequent use as feed and biomass raw materials; Second, the crude fiber is rich, with the content of 18%-25%, and the soluble fiber is the main one, with loose structure, which can improve the gastrointestinal peristalsis of livestock in the field of feed and enhance the air permeability of soil in the field of organic fertilizer. In addition, it also contains a small amount of protein (3%-5%), vitamins and minerals, and its ingredients are natural and non-toxic, which is different from industrial waste residue and can realize the full chain resource utilization.

Advantages of belt press dewatering machine:

The water content of sweet potato residue is usually as high as 85%-90%, and it contains a lot of starch and fiber. The belt press dewatering machine is used to effectively dehydrate its characteristics and effectively protect the fiber from being destroyed. The sweet potato residues dewatering machine is treated by pre-pressing and press classification. The three-stage treatment process (gravity dehydration zone, wedge pre-pressing zone and high-pressure press zone) can gradually separate moisture, fully squeeze the moisture in the gap between materials, effectively reduce its moisture content, greatly reduce the material volume, and improve the subsequent storage, post-processing cost and transportation efficiency.

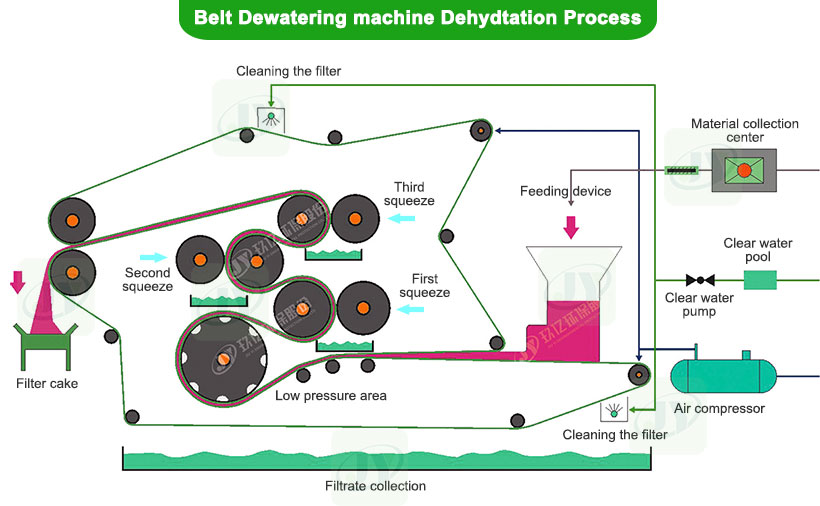

Dehydration Principle Of Sweet Potato Residues Belt Dewatering Machine

Transport materials with a moisture content of 80% -90% to the hopper of the dewatering machine through a conveyor, and evenly spread the materials on the filter belt through a feeder. The filter belt moves with the operation of the equipment, and the limit plate scrapes the material layer flat. At the same time, control the thickness of the material to make it completely uniform and consistent.

Then, two fully tensioned circular filter belts are clamped between the material layer, driven by the driving roller. The material is continuously and repeatedly squeezed through the pre press dehydration zone, low-pressure zone, and three sets of pressure roller high-pressure zone to remove a large amount of moisture.

Adjust the extrusion pressure and feeding speed according to different material characteristics to meet customers’ requirements for material moisture.

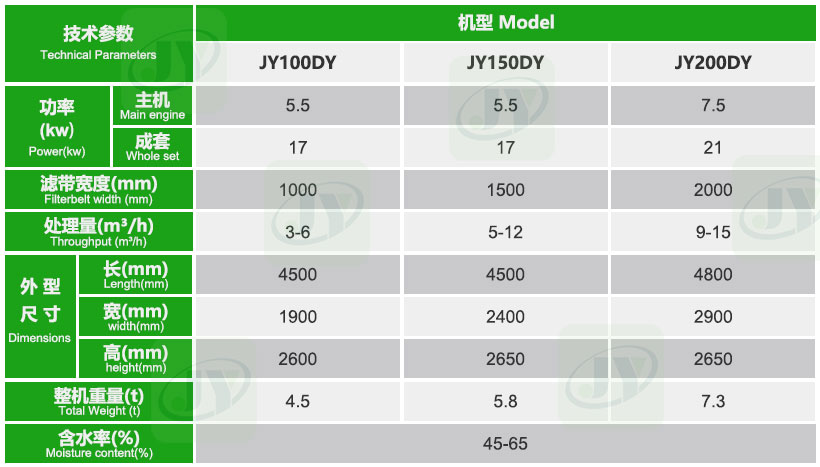

Belt Press Dehydrators Technical Parameter

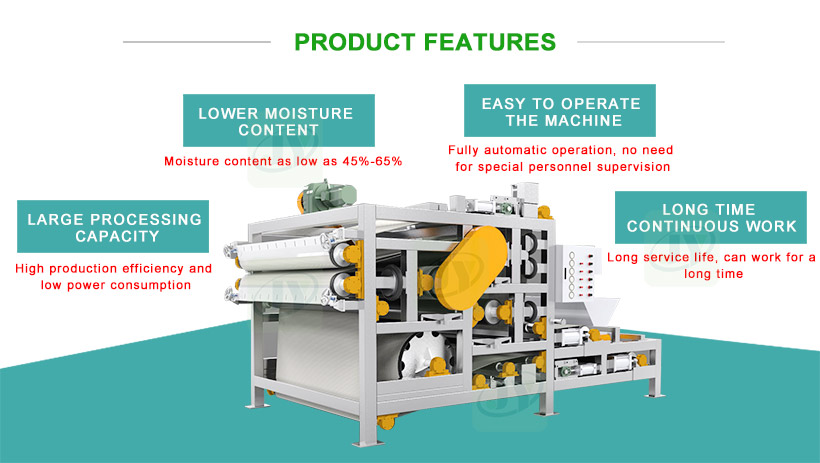

JIUYI Brand Belt Press Dewatering Machine Feature

JIUYI dehydrators is a new generation of high-efficiency press dewatering equipment independently developed by us based on years of material dewatering experience and combined with similar dewatering equipment technologies at home and abroad. It has successfully solved the problem of continuous large-scale and deep dehydration of different materials.

1. Low power consumption, low noise, high production efficiency.

2. The machine adopts an ultra long filtering zone, combined with strong pressure rollers for multiple dehydrations, resulting in high dehydration efficiency and large processing capacity.

3. Automatic filter cloth cleaning system, no manual intervention required.

4. Adopting an automatic fabric device, the feeding is smooth and reliable.

4. Select high-quality anti-corrosion materials and components for processing and manufacturing.

5. Advanced and reliable filter belt correction and tensioning device can ensure long-term stable operation.

6. Variable frequency drive control, adjustable production speed.

7. It can run continuously for 24 hours, with high automation, simple operation, and easy maintenance.

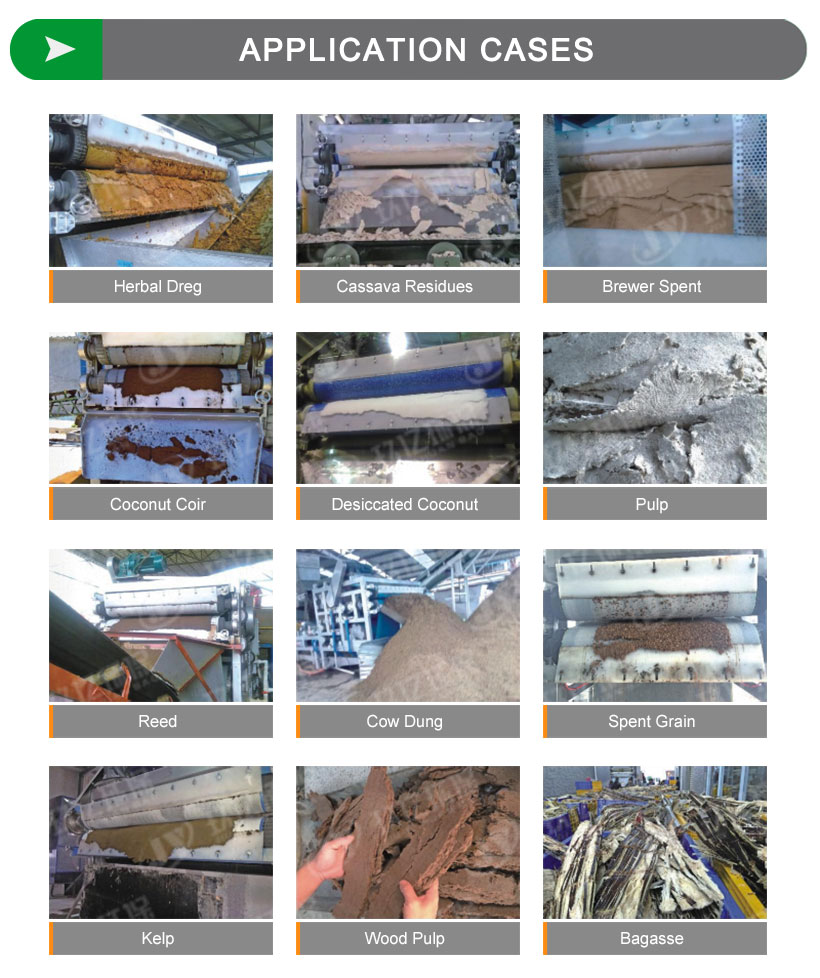

8. Advanced structural design with a wide range of applications.

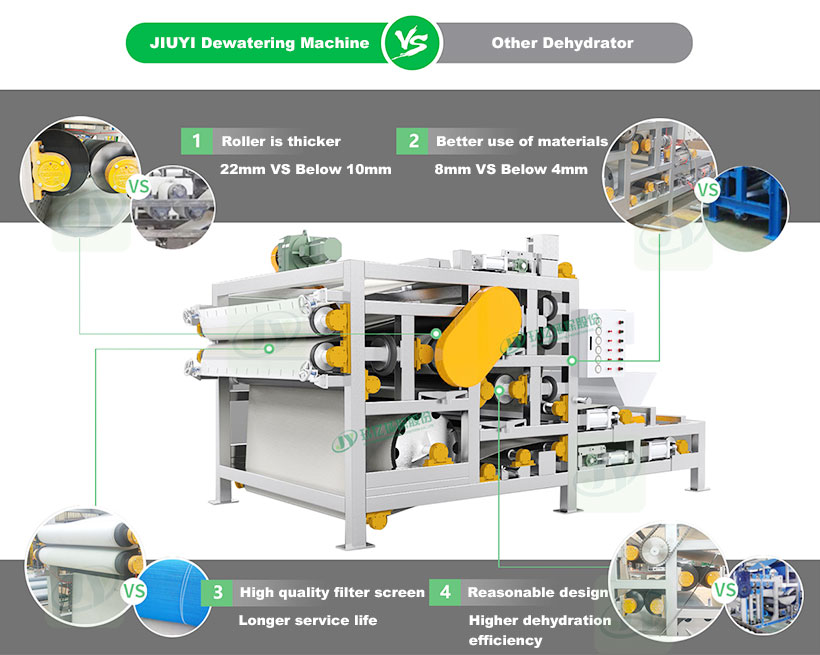

9. The driving roller and squeezing roller of the dehydrator are coated with high-quality materials.

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment