Brewery Spent Grains Belt Dehydrators Equipment Introduction

Characteristics of Brewery Spent Grains:

Brewery spent grains, also known as beer lees, has a high moisture content of 75% -85%, a relatively loose texture, and contains a large amount of organic components such as fiber, protein, and residual sugar. It has certain nutritional value, but is also prone to spoilage and deterioration. At the same time, its particle size is uneven, and it has a certain viscosity in a wet state, making dehydration difficult. Traditional dehydration methods are inefficient and ineffective.

Advantages of belt dewatering machine:

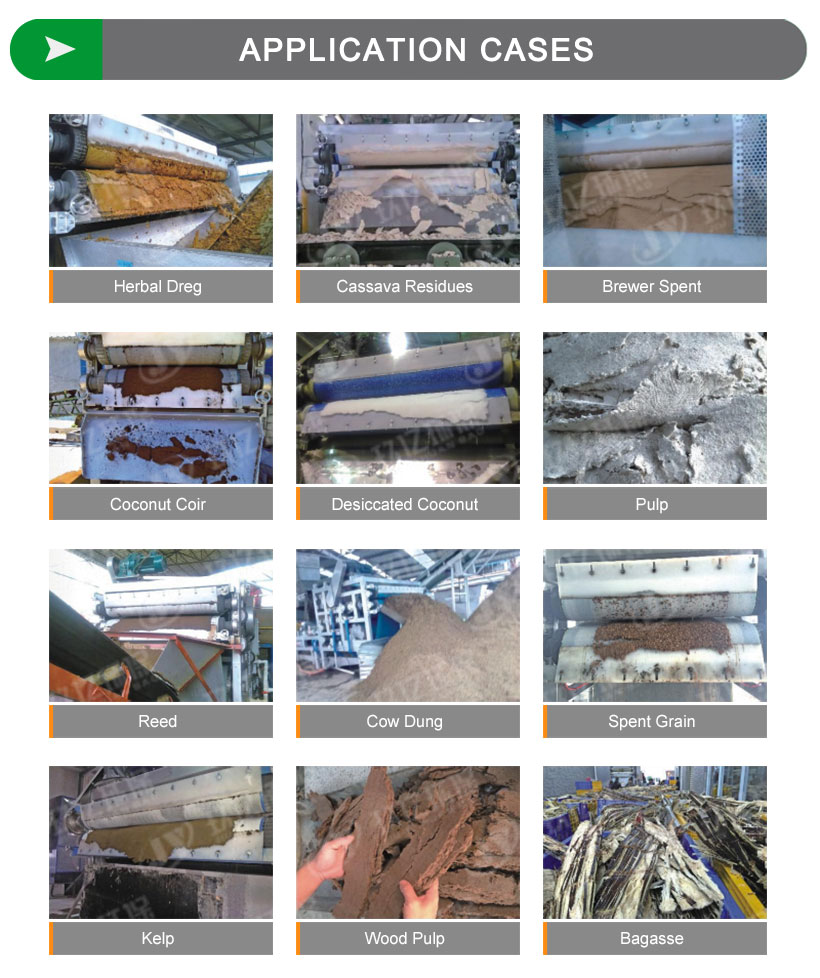

The belt dehydrators adopts continuous operation and can adapt to the high moisture content and viscosity of beer waste residue. Through multiple stages such as gravity dewatering, wedge pre pressure dewatering, and press dewatering, the moisture content of the waste residue is effectively reduced to 40% -50%. The equipment has a high degree of automation and can operate continuously 24 hours a day, reducing manual intervention and lowering labor costs. Moreover, the filter has strong anti clogging ability, easy cleaning, and can effectively ensure dehydration efficiency and quality. The dehydrated beer waste residue is easy to transport and utilize as a resource, such as being used as feed raw material, organic fertilizer raw material, etc. Brewery Spent Grains Beer Dregs Belt Dehydrators are highly suitable for dehydration treatment of various beer waste residues.

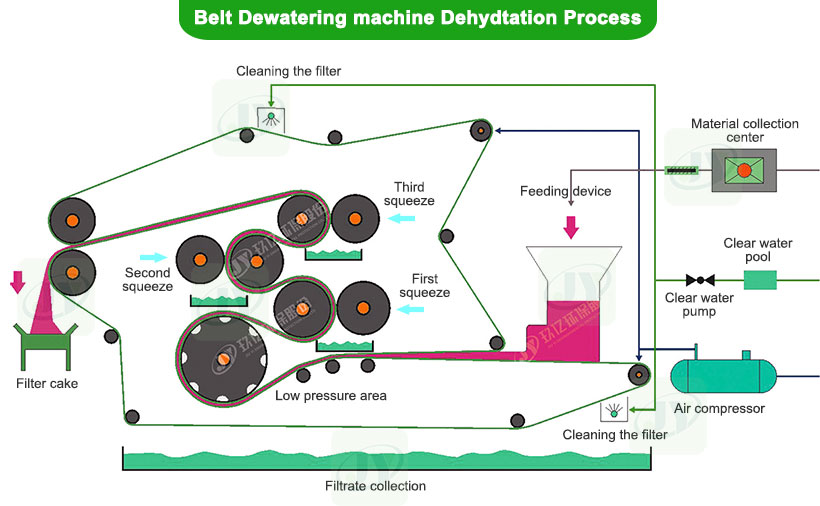

Dehydration Principle Of Brewery Spent Grains Beer Dregs Belt Dewatering Machine

Transport materials with a moisture content of 80% -90% to the hopper of the dewatering machine through a conveyor, and evenly spread the materials on the filter belt through a spiral feeder. The filter belt moves with the operation of the equipment, and the limit plate scrapes the material layer flat. At the same time, control the thickness of the material to make it completely uniform and consistent;

Then, two fully tensioned circular filter belts are clamped between the material layer, driven by the driving roller. The material is continuously and repeatedly squeezed through the pre press dehydration zone, low-pressure zone, and three sets of pressure roller high-pressure zone to remove a large amount of moisture.

Adjust the extrusion pressure and feeding speed according to different material characteristics to meet customers’ requirements for material moisture.

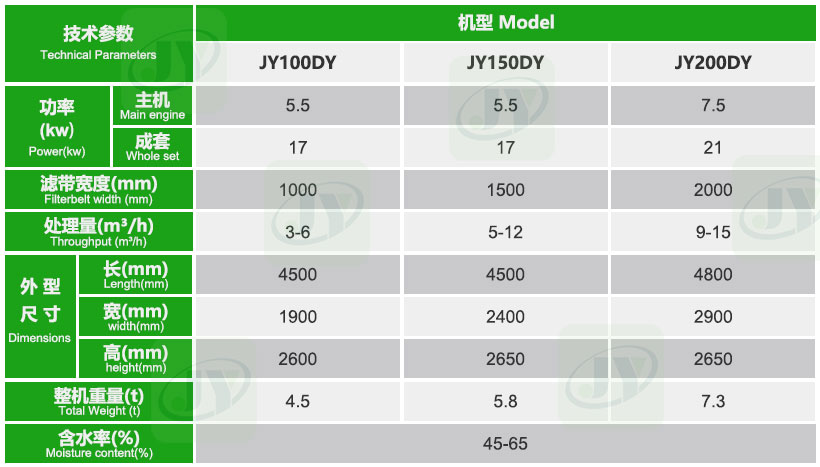

Belt Press Dehydrators Technical Parameter

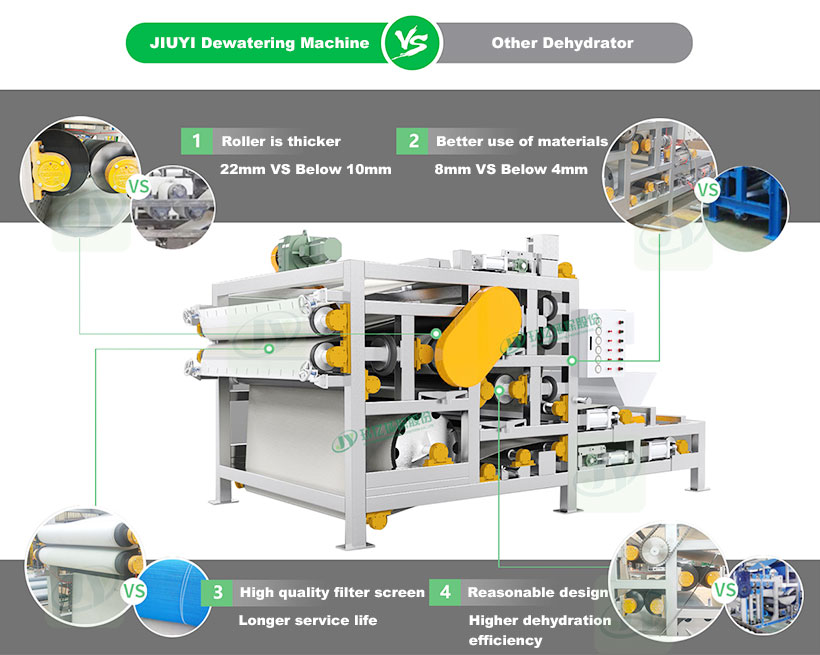

JIUYI Brand Belt Press Dehydrators Feature

JIUYI dehydrators is a new generation of high-efficiency press dewatering equipment independently developed by us based on years of material dewatering experience and combined with similar dewatering equipment technologies at home and abroad. It has successfully solved the problem of continuous large-scale and deep dehydration of different materials.

1. Low power consumption, low noise, high production efficiency.

2. The machine adopts an ultra long filtering zone, combined with strong pressure rollers for multiple dehydrations, resulting in high dehydration efficiency and large processing capacity.

3. Automatic filter cloth cleaning system, no manual intervention required.

4. Adopting an automatic fabric device, the feeding is smooth and reliable.

4. Select high-quality anti-corrosion materials and components for processing and manufacturing.

5. Advanced and reliable filter belt correction and tensioning device can ensure long-term stable operation.

6. Variable frequency drive control, adjustable production speed.

7. It can run continuously for 24 hours, with high automation, simple operation, and easy maintenance.

8. Advanced structural design with a wide range of applications.

9. The driving roller and squeezing roller of the dehydrator are coated with high-quality materials.

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment