Brewery waste residues (such as distiller’s grains and brewer’s grains) contains high fiber and high protein, and the moisture content of fresh waste residue often reaches 80%-95%.

Belt dewatering machine can accurately match its characteristics. In the actual measurement of a brewery in Shandong, China, the equipment can treat 18-22 tons of wet waste residue per hour, and the water content after dehydration is reduced to 45%-60%, which is 35% higher than that of the traditional centrifugal dewatering machine, and protein denaturation due to high-speed rotation is avoided (protein retention rate is over 90%).

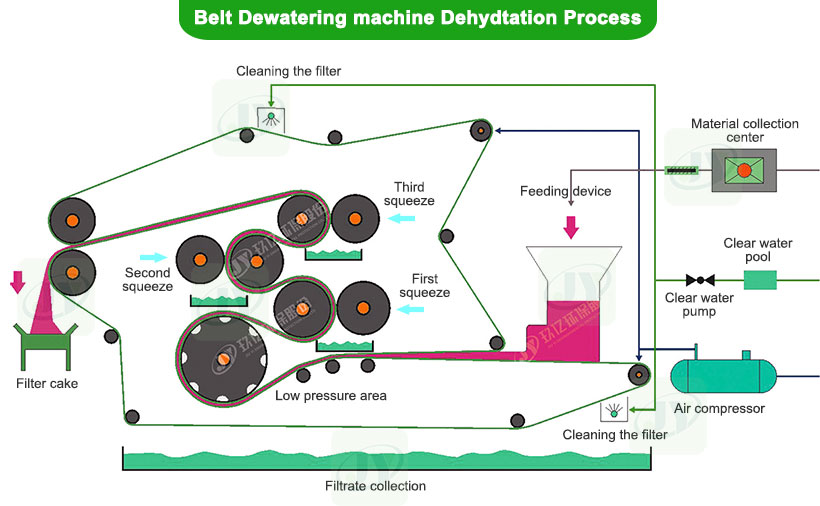

Using three-stage pressing (gravity drainage → wedge preloading → high pressure rolling), free water and fiber bound water can be separated step by step, and the energy consumption per ton of slag is only 9-12kW/h, which is 25% less than that of plate-and-frame filter press.

The annual treatment of 10,000 tons can reduce the electricity bill by more than 100,000 yuan. The continuous operation design adapts to the continuous production mode of the winery, and the single-shift operation does not need to stop and clean up, which greatly improves the processing efficiency.

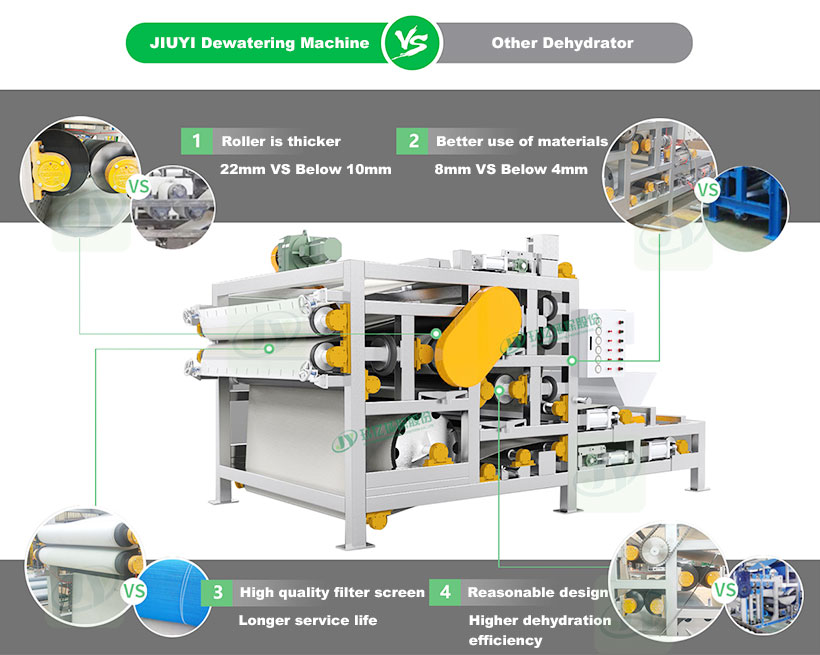

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment

Belt Dehydrator, Belt Press Filter, Cocopeat & Cassava Residues Dewatering Machine Manufacturer In China – JIUYI Dehydration Equipment