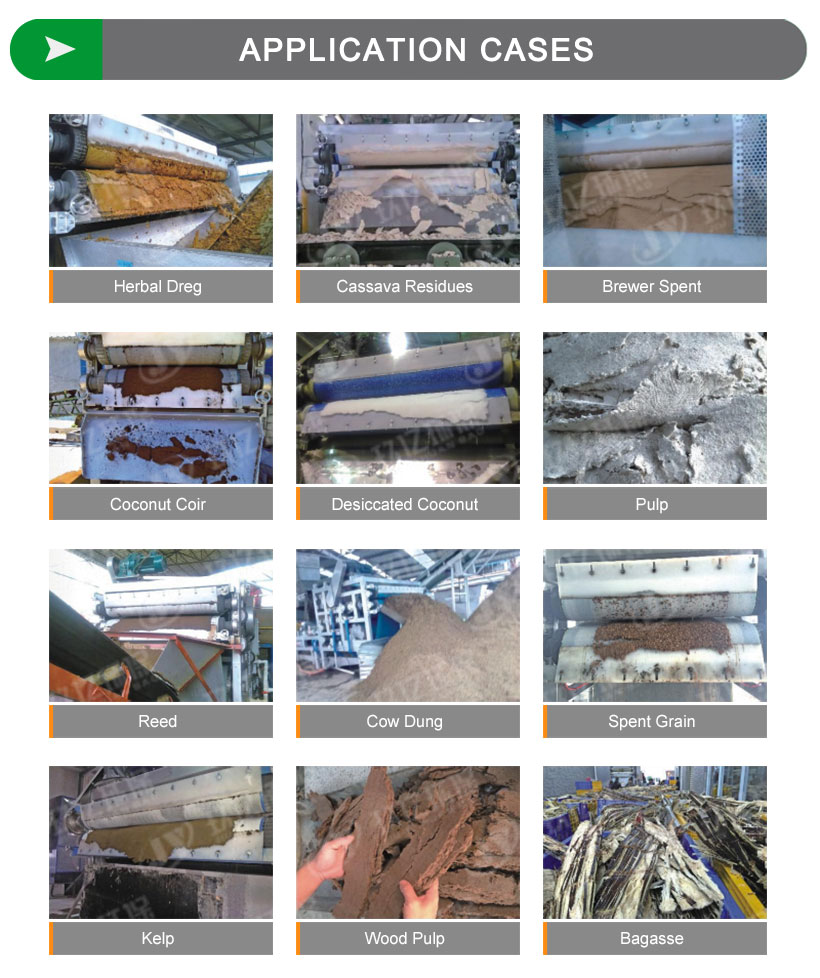

牛の糞 & Manure Belt Dewatering Machine Equipment Introduction

Characteristics of Cow Dung & Manure:

Fresh cow manure usually has a moisture content of 80% -90%, with a viscous texture and fiber impurities such as undigested straw and grass shavings, which are prone to clumping and sticking. When stored, it is easy to breed bacteria and produce odors. During transportation, weight loss may also occur due to water loss, causing inconvenience in handling.

Cow manure contains a large amount of organic matter (about 60% -80% of dry matter), as well as essential nutrients such as nitrogen, phosphorus, and potassium for plants. It also contains trace elements and humus, which have the basic conditions for conversion into fertilizers or energy. If untreated and directly discharged or piled up, cow manure will pollute soil and water sources, and release greenhouse gases such as methane;

But after scientific processing, it can be converted into clean energy or high-quality fertilizers, achieving the goal of “turning waste into treasure” and meeting the requirements of environmental protection and circular economy.

After dehydration, the volume of cow manure can be reduced by 40% -60%, and the weight can be greatly reduced. This not only saves warehouse storage space, but also reduces transportation frequency and cost, while reducing the risk of odor diffusion and spoilage caused by moisture.

Advantages of belt press dewatering machine:

The use of a belt press dewatering machine for extrusion dewatering is gentle and can maximize the retention of organic matter, nitrogen, phosphorus, potassium and other nutrients in cow manure, avoiding nutrient loss caused by high-temperature dewatering.

Dehydrated dry cow manure can be directly used for:

- Composting and fermenting to produce organic fertilizer for use in farmland and orchards;

- As a biomass fuel, it can replace some coal and straw;

- Processed into aquaculture bedding to achieve recycling.

cow manure processing belongs to large-scale production, and the belt press dewatering machine can continuously feed and discharge without intermittent shutdown, which can match the batch production rhythm of cow manure.

By adjusting parameters such as the running speed of the filter belt, the pressure of the squeezing roller, and the tension, the moisture content of the dehydrated cow manure can be flexibly controlled to avoid fiber breakage caused by excessive squeezing.

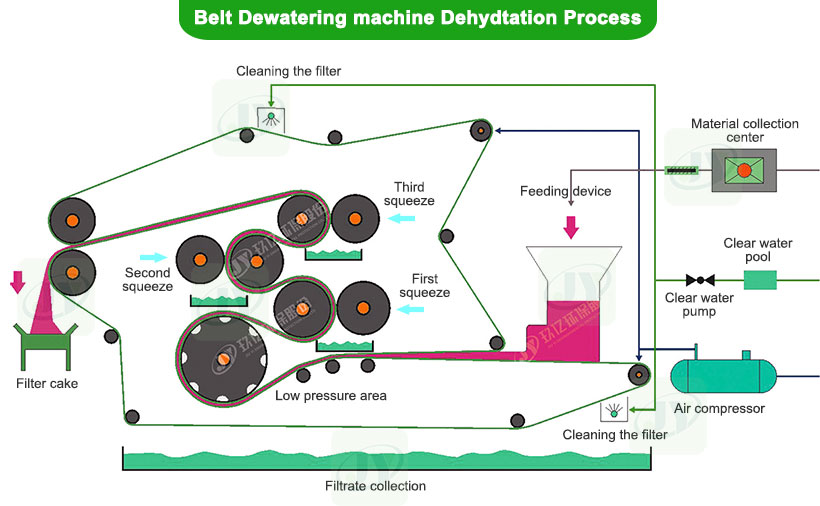

Dehydration Principle Of Cow Dung & Manure Belt Dewatering Machine

含水率のある材料を輸送します。 80% -90% コンベアを経て脱水機のホッパーへ, スパイラルフィーダーを通してフィルターベルト上に材料を均等に広げます. 装置の動作に合わせてフィルターベルトが動きます, そしてリミットプレートが材料層を平らに削り取る. 同時に, 材料の厚さを制御して完全に均一かつ一貫したものにする;

それから, 完全に張力を掛けた 2 つの円形フィルター ベルトが材料層の間にクランプされています。, 駆動ローラーによって駆動される. 材料はプリプレス脱水ゾーンを通して連続的かつ繰り返し絞り出されます。, 低気圧地帯, 3組の加圧ローラー高圧ゾーンで大量の水分を除去.

顧客に合わせて、さまざまな材料特性に応じて押出圧力と供給速度を調整します’ 材料の水分要件.

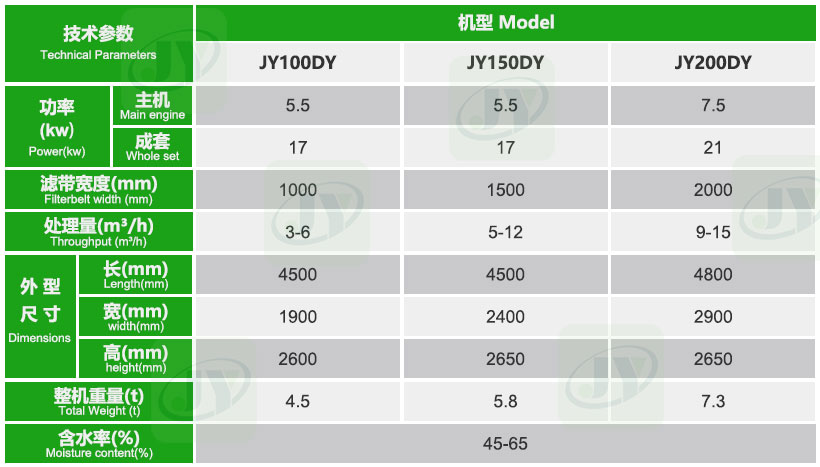

ベルトプレス脱水機の技術パラメータ

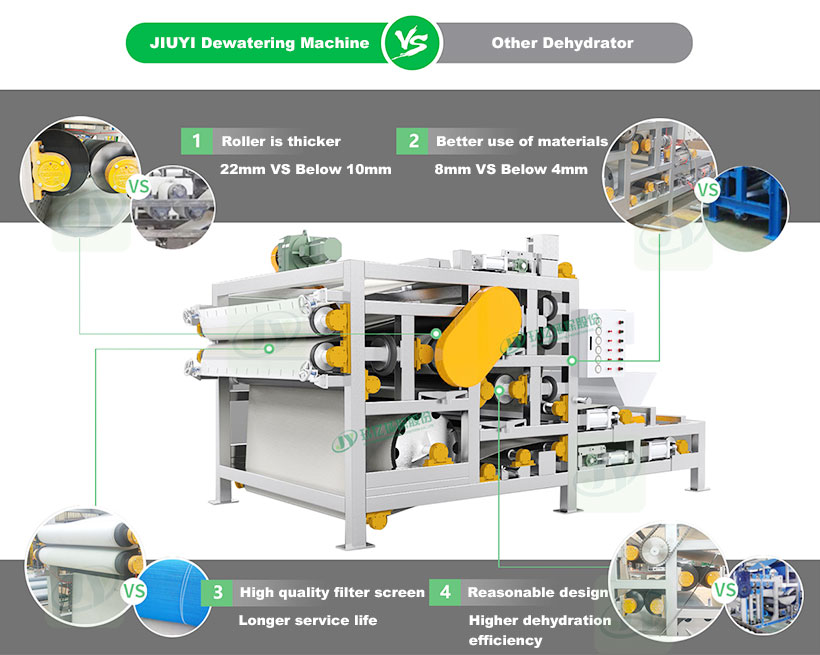

JIUYI Brand Belt Press Dewatering Machine Feature

JIUYI脱水機は、長年の材料脱水経験に基づいて当社が独自に開発し、国内外の同様の脱水装置技術を組み合わせた新世代の高効率プレス脱水装置です。. 異なる材料の連続大規模かつ深度の脱水の問題を解決することに成功しました。.

1. 低消費電力, 低騒音, 高い生産効率.

2. この機械は超長い濾過ゾーンを採用しています, 強力な加圧ローラーと組み合わせて複数回の脱水が可能, 高い脱水効率と大きな処理能力を実現.

3. 自動ろ布洗浄装置, 手動介入は必要ありません.

4. 自動ファブリック装置の採用, 給餌はスムーズで信頼性が高い.

4. 加工と製造には高品質の耐食材料とコンポーネントを選択します.

5. 高度で信頼性の高いフィルターベルト修正および張力装置により、長期にわたる安定した動作が保証されます。.

6. 可変周波数駆動制御, 調整可能な生産速度.

7. 連続して実行できます 24 時間, 高度な自動化により, 簡単な操作, メンテナンスも簡単.

8. 幅広い用途に対応する高度な構造設計.

9. 脱水機の駆動ローラーと絞りローラーに高級素材をコーティング.

ベルト脱水機, ベルトプレスフィルター, ココピート & 中国のキャッサバ残渣脱水機メーカー – JIUYI 脱水装置

ベルト脱水機, ベルトプレスフィルター, ココピート & 中国のキャッサバ残渣脱水機メーカー – JIUYI 脱水装置